AI technologies streamline brick manufacturing processes by optimizing production line efficiency. Machine learning algorithms analyze data from various stages to predict maintenance needs, reducing downtime and improving output. Quality control is enhanced through computer vision systems that detect defects in real-time, ensuring only the highest quality bricks proceed to market. Predictive analytics also aid in inventory management, allowing manufacturers to align production with demand accurately.

AI usage in brick manufacturing

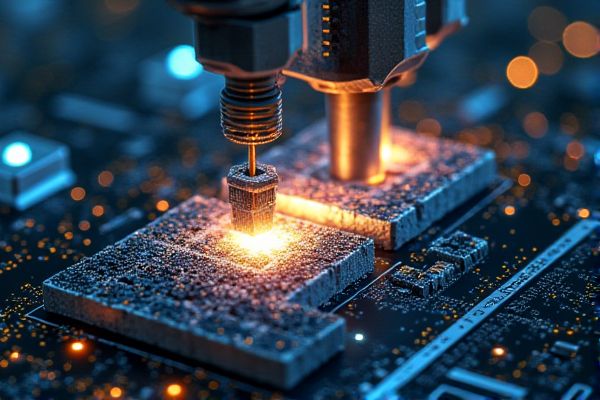

Automation

AI can significantly improve efficiency in brick manufacturing by optimizing production processes. Automation systems, such as robotic arms, can handle repetitive tasks, reducing labor costs and minimizing human error. Implementing AI-driven analytics can enhance quality control, ensuring that every batch of bricks meets precise standards. For instance, a company like Wienerberger may experience reduced waste and increased productivity through these technological advancements.

Predictive Maintenance

AI can enhance brick manufacturing through predictive maintenance, which can reduce downtime and improve efficiency. By analyzing machine data, AI models can predict equipment failures before they occur, minimizing disruptions in production. For example, a company like Caledonia Brick could implement such technology to optimize their operations. This approach can lead to cost savings and increased productivity in the manufacturing process.

Quality Control

AI can enhance quality control in brick manufacturing by analyzing production data for defects. Implementing machine learning algorithms can identify inconsistencies that human inspectors might overlook. Companies like Wienerberger have started using AI to optimize their processes and improve product quality. This integration offers the potential for reduced waste and increased efficiency in the production line.

Energy Efficiency

AI has the potential to significantly enhance energy efficiency in brick manufacturing by optimizing production processes. For instance, an AI system can analyze temperature and humidity in real-time to adjust the drying phase, thereby saving energy. Predictive maintenance powered by AI can also minimize downtime, leading to less energy wastage. The integration of these technologies might provide manufacturers with a competitive edge in the construction industry.

Supply Chain Optimization

AI can enhance brick manufacturing by optimizing production processes, leading to reduced waste and increased efficiency. Implementing machine learning algorithms can predict equipment failures, ensuring maintenance is performed proactively at facilities like ABC Bricks Co. Supply chain optimization through AI can facilitate better demand forecasting and inventory management, helping manufacturers respond quickly to market changes. The potential for cost savings and improved resource management makes AI a valuable asset in the brick industry.

Customization

AI can optimize the brick manufacturing process by analyzing production data to enhance efficiency and reduce waste. Customization options increase, allowing manufacturers to create unique brick designs tailored to specific architectural needs. For instance, institutions like the University of Cambridge are exploring AI methods to improve material properties. This approach could lead to significant cost savings and better resource utilization in the long run.

Environmental Impact

The integration of AI in brick manufacturing can enhance operational efficiency and reduce waste. With predictive analytics, manufacturers can optimize production schedules and adjust raw material usage, potentially minimizing environmental impact. For example, a company like Wienerberger might leverage AI to improve energy consumption during the firing process. This approach not only lowers carbon emissions but also presents an opportunity for cost savings through smarter resource management.

Cost Reduction

AI can enhance efficiency in brick manufacturing by optimizing production processes and minimizing waste. By analyzing data from previous batches, AI models can predict the ideal mixture of raw materials, potentially lowering costs. For example, institutions like the Manufacturing Institute have explored AI applications to improve operational efficiency in various sectors, including construction materials. This integration of technology may offer a significant competitive advantage through reduced overhead and enhanced product quality.

Workforce Training

AI can enhance efficiency in brick manufacturing by optimizing production processes and reducing waste. With proper workforce training, employees can effectively integrate AI technologies, leading to increased productivity. Manufacturers like ABC Brick Co. could potentially see improvements in quality control through data analysis provided by AI systems. This strategic approach may provide a competitive edge in a rapidly evolving market.

Process Optimization

AI can enhance process optimization in brick manufacturing by analyzing production data to identify inefficiencies. For example, using machine learning algorithms, manufacturers could optimize kiln temperatures and timings to improve energy efficiency. This can lead to reduced costs and increased product quality. The integration of AI technologies offers a significant possibility for manufacturers to gain a competitive advantage in the industry.

techknowy.com

techknowy.com