AI technologies enhance operational efficiency in the mining industry by optimizing exploration and extraction processes. Predictive maintenance powered by AI algorithms minimizes equipment downtime, leading to significant cost savings. Machine learning models analyze geological data, improving resource estimation and reducing the risks associated with mining activities. Automation of drilling and transportation processes not only increases safety but also maximizes productivity and reduces environmental impacts.

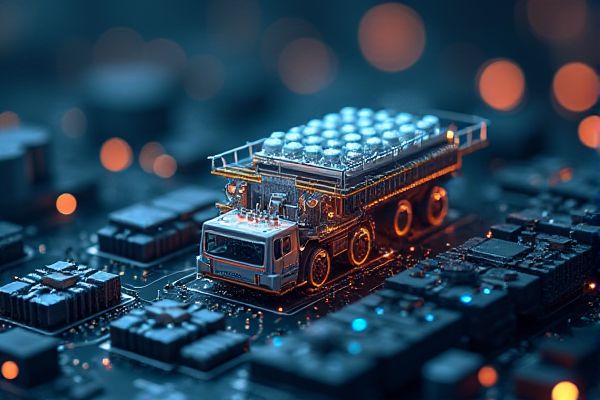

AI usage in mining industry

Predictive Maintenance

AI usage in the mining industry can enhance predictive maintenance by analyzing equipment data to anticipate failures before they occur. For example, machines like conveyor belts can be monitored using AI algorithms to identify wear and tear patterns. This proactive approach can potentially reduce downtime and minimize repair costs. Implementing AI-driven solutions can improve operational efficiency and safety in mining operations.

Mineral Exploration

AI has the potential to significantly enhance mineral exploration by analyzing vast datasets to identify promising sites. Algorithms can assess geological data and past exploration results to improve decision-making processes. For instance, remote sensing data can be leveraged to detect mineral deposits more efficiently than traditional methods. This technological advancement may lead to reduced exploration costs and increased discovery rates for companies like Barrick Gold.

Autonomous Vehicles

The integration of AI in the mining industry can enhance operational efficiency by optimizing resource extraction and reducing downtime. Autonomous vehicles, such as driverless trucks, are being employed to transport materials safely and efficiently across mining sites. Companies like Komatsu are already experimenting with this technology, showing potential improvements in safety and productivity. The adoption of AI and autonomous systems could lead to significant cost savings and reduced environmental impact.

Safety Monitoring

AI usage in the mining industry can enhance safety monitoring by analyzing real-time data from equipment and environmental sensors. For example, predictive analytics can identify potential hazards, allowing companies like Rio Tinto to implement preventative measures before accidents occur. The integration of AI technologies in safety protocols can lead to reduced injury rates and improved compliance with regulations. Companies may increase operational efficiency by minimizing downtime related to safety issues.

Resource Optimization

AI technologies can enhance resource optimization in the mining industry by analyzing vast datasets for more informed decision-making. For example, AI algorithms can predict equipment maintenance needs, reducing downtime and improving efficiency for companies like Rio Tinto. The use of AI can result in minimized waste and increased yield from mining operations, potentially lowering costs. Embracing AI may also lead to advancements in safety protocols, reducing workplace hazards and enhancing overall operational effectiveness.

Environmental Impact Assessment

AI can enhance the efficiency of Environmental Impact Assessment (EIA) in the mining industry by analyzing large datasets to predict potential environmental changes. By incorporating AI-driven models, companies might identify ecological risks before they escalate, allowing for proactive mitigation strategies. For example, an institution like the World Resources Institute may utilize AI tools to improve sustainability practices. This possibility can lead to a more balanced approach between resource extraction and environmental preservation.

Data Analytics and Modelling

AI has the potential to significantly enhance efficiency in the mining industry through data analytics and modeling. By leveraging real-time data, companies can optimize resource extraction and reduce operational costs. For instance, predictive modeling can forecast equipment failures, minimizing downtime and maximizing productivity. Embracing such technologies may position firms like Rio Tinto to gain a competitive advantage in an evolving market.

Energy Consumption Management

AI technology in the mining industry offers the possibility of optimizing energy consumption management. By analyzing operational data, AI can identify inefficiencies and suggest improvements, potentially reducing overall energy costs. For instance, companies like Rio Tinto are exploring AI solutions to minimize energy waste in their extraction processes. Implementing such systems could lead to significant environmental benefits alongside cost savings.

Real-time Process Control

AI usage in the mining industry can enhance real-time process control, potentially leading to increased efficiency and reduced operational costs. For instance, companies like Rio Tinto utilize AI algorithms to monitor machinery and predict maintenance needs. With optimized resource allocation, mining operations can respond more swiftly to changing conditions, improving overall productivity. The integration of AI technologies can also minimize environmental impact by enabling smarter resource extraction methods.

Workforce Training and Augmentation

AI implementation in the mining industry can enhance workforce training through simulation-based learning, allowing workers to practice in a risk-free environment. For example, institutions like the University of Alberta are exploring AI-driven training modules that can tailor learning experiences to individual needs. This personalized approach may lead to increased efficiency and safety on-site, potentially reducing accidents and operational downtime. The possibility of augmented reality applications further boosts the chance of improving skill retention and practical knowledge among workers.

techknowy.com

techknowy.com